- Products

- Technologies

- IR LayerRelease™ Technology

- MLE™ - Maskless Exposure Technology

- Nanoimprint Lithography (NIL) - SmartNIL®

- Wafer Level Optics

- Optical Lithography

- Resist Processing Technology

- Temporary Bonding and Debonding

- Eutectic Bonding

- Transient Liquid Phase (TLP) Bonding

- Anodic Bonding

- Metal Diffusion Bonding

- Fusion and Hybrid Bonding

- Die-to-Wafer Fusion and Hybrid Bonding

- ComBond® Technology

- Metrology

- Company

- Careers

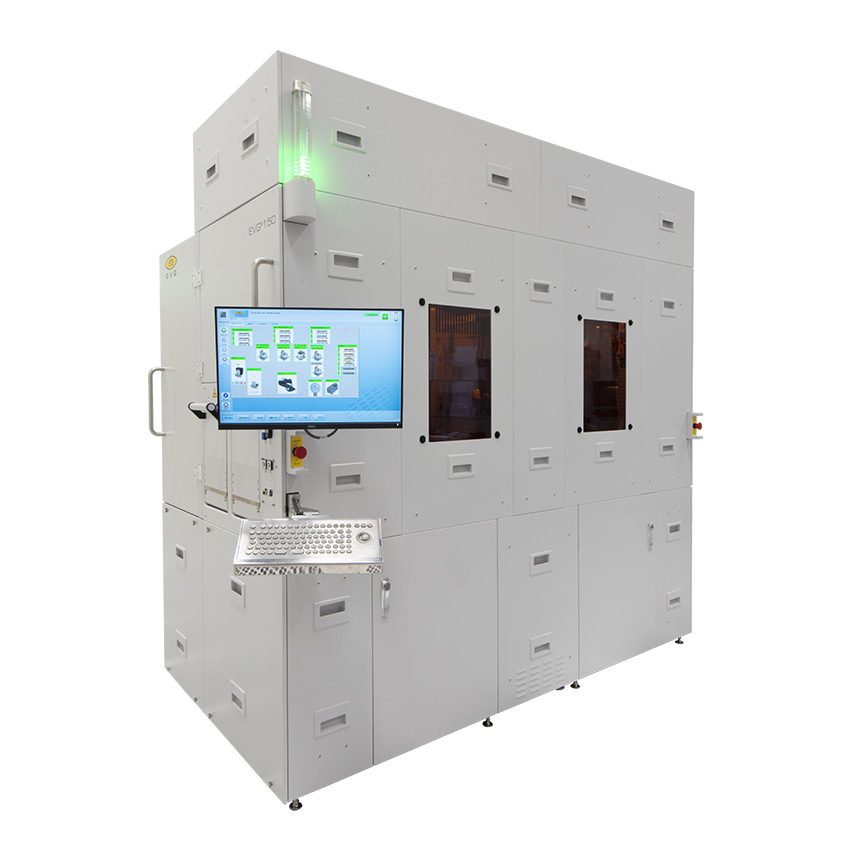

EVG®150

Automated Resist Processing System

The EVG®150 is a fully-automated resist processing system providing highthroughput performance and supporting wafers up to 200 mm in diameter.

Designed as a fully modular platform, the EVG150 provides automated spin/spray/develop processes with high throughput. A new ultra-compact design with footprint < 3 m2 and redesigned modules enables easy access of individual chambers as well as the robot area. To minimize downtime, single modules can be serviced while the remaining system can be kept up and running. The system features four wet processing modules and up to 20 bake/chill units. Outstanding throughput values for real-life processes can be achieved by using a high-speed, high-accuracy robot and advanced scheduler algorithms. Even though the system exhibits a very compact design, up to 12 pumps and resist bottles can be installed inside the main frame. The EVG150 guarantees highly uniform coats ranging from demanding thick resist applications down to sub-micron layers.

Wafers with high topography can be uniformly coated by EVG’s proprietary OmniSpray ultrasonic atomization technology, where traditional coating encounters limitations. Up to four XY spray coat modules can be installed in the system, which allows unrivalled spray coating throughput.

Versatile combinations of multi-functional modules provide great opportunities in many fields of application like MEMS, image sensors, advanced packaging, RF, 5G, 3D sensing, photonics, automotive and power electronics manufacturing.

Features

- Wafer sizes up to 200 mm

- Four wet process modules in any combination

- Up to 20 hot/chill plates stacked inside the tool

- Two or four loadports; cassette stations in full compliance with SEMI S8 ergonomics standard

- Encapsulated chambers prevent cross-contamination

- Chemistry within base frame: Pumps and resists in shortest distance to point of use

- Sophisticated robot handling for highest throughput; placement accuracy < 50 μm

- Handling of thick or ultrathin, fragile, bowed or small-diameter wafers

- Flexible pressure dispense system with high-precision flow meters for spin coating; bottle sizes up to 1 gal

- Complete temperature control for resist and developer lines

- OmniSpray®: conformal coating of extreme topographies; up to two nozzles per module

- Bake modules with a uniformity <± 0.4 % across the whole temperature range up to 250 °C

- Optional: solvent bakes with double-side heating and hightemperature bakes up to 350 °C

- Extensive range of supported materials: thin and thick negative and positive resists, dielectrics, colored resists, adhesives & polyimides

- Process technology excellence and development service

- GUI with multi-user concept

- Smart process control and data analysis feature [EVG CIMFramework]

- Integrated analysis features for process and machine control

- Equipment and process performance tracking feature

- Parallel/queueing task processing feature

- Smart handling features

- Occurrence and alarm analysis

- Smart maintenance management and tracking

Technical Data

| Wafer diameter (substrate size) |

|---|

| up to 200 mm |

| Available modules |

|---|

| Spin coat / OmniSpray® / Develop |

| Bake / Chill / Vapor Prime |

| Wafer handling options |

|---|

| Double EE / edge handling |

| Bowed / warped / thin wafer handling |

| Dispense options |

|---|

| Various resist dispense pumps to cover a wide range of viscosities up to 52000 cP |

| Constant pressure dispense systems |

| EBR / BSR / pre-wet / liquid priming |

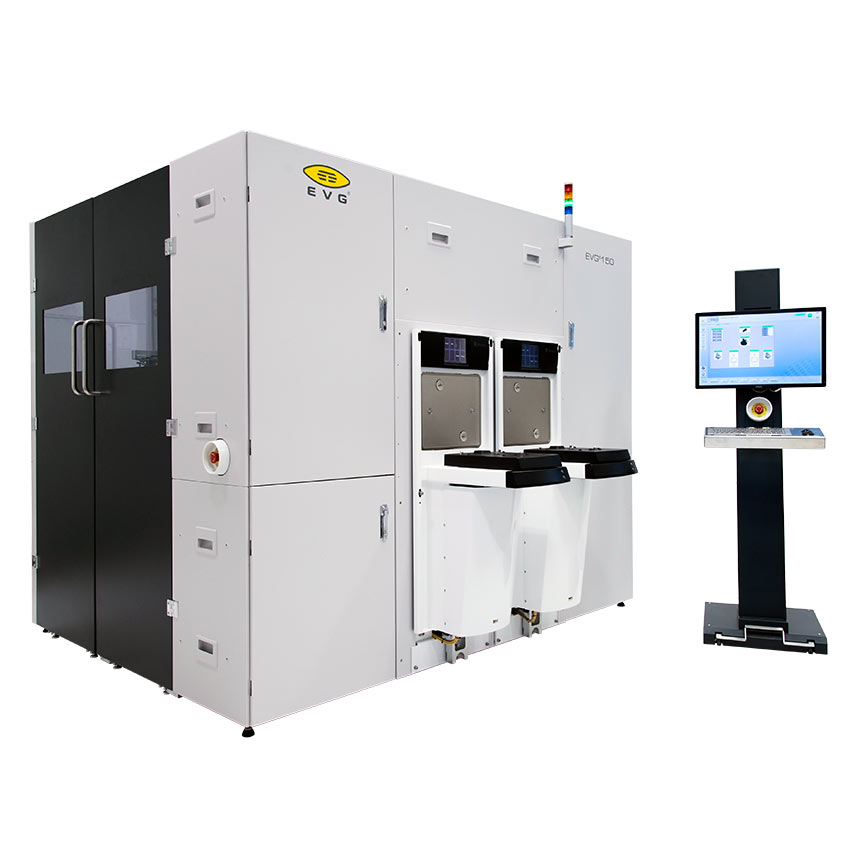

The EVG®150 is a fully-automated resist processing system providing highthroughput performance and supporting wafers up to 300 mm in diameter.

Designed as a fully modular platform, the EVG150 allows automated spray/spin/develop processes and high-throughput performance. The EVG150 guarantees highly uniform coats and improved repeatability. Wafers with high topography can be uniformly coated by EVG’s OmniSpray technology, where traditional spin coating encounters limitations.

Features

- Wafer sizes up to 300 mm

- Up to six process modules

- Customizable number - up to twenty bake/chill/vapor prime stacks

- Up to four FOUP load ports or cassette loading

- Available modules include Spin Coat, Spray Coat, NanoCoat™, Develop, Bake/Chill/Vapor/Prime

- EV Group’s proprietary OmniSpray® ultrasonic atomization technology provides unmatched process results when it comes to conformal coating of extreme topographies

- Optional NanoSpray™ module achieves conformal coating of 300-micron deep patterns with aspect ratios up to 1:10 and vertical sidewalls

- Extensive range of supported materials

- Bake modules for up to 250 °C

- Megasonic technology for cleaning, sono-chemical processing and developing improves process efficiency and lowers the process time from hours to minutes

- Sophisticated and field-proven robot handling with dual end-effector capability ensures continuous high throughput

- Handling of thick or ultra-thin, fragile, bowed or small-diameter wafers

- Versatile combinations of multi-functional modules for spin and spray coating, developing, bake and chill provide great opportunities in many fields of application

- EFEM (Equipment Frontend Module) and optional FSS (FOUP Storage System)

- Process technology excellence and development service

- Multi-user concept (unlimited number of user accounts and recipes, assignable access rights, different user interface languages)

- Smart process control and data analysis feature [EVG CIMFramework]

- Integrated analysis features for process and machine control

- Equipment and process performance tracking feature

- Parallel/queueing task processing feature

- Smart handling features

- Occurrence and alarm analysis

- Smart maintenance management and tracking

Technical Data

| Number of modules |

|---|

| Process modules: up to 6 |

| Bake / chill modules: up to 20 |

| Industrial automation features |

|---|

| Ergo load cassette stations / SMIF loadports / SECS/GEM / FOUP load ports |

| Smart process control & data analysis features (framework SW platform) |

|---|

| Integrated analysis features for process and machine control |

| Parallel task / queueing task processing feature |

| Equipment and process performance tracking feature |

| Smart handling features |

| Occurences & alarms analysis / smart maintenance management & tracking |

| Wafer diameter (substrate size) |

|---|

| Up to 300 mm |

| Available modules |

|---|

| Spin coat / OmniSpray® / develop |

| Bake / chill |

| Wafer handling options |

|---|

| Single/double EE / edge handling / wafer flipping |

| Bowed / warped / thin wafer handling |

| Dispense options |

|---|

| Various resist despense pumps to cover a wide range of viscosities up to 52000 cP |

| Liquid priming / pre-wet / bowl wash |

| Edge bead removal (EBR) / back-side rinse (BSR) |

| Constant pressure dispense systems / syringe dispense system |

| Resist dispense pump features flowmonitoring |

|---|

| Programmable dispense rate / programmable volume / programmable suck-back |

| Ultrasonic |

| Additional module options |

|---|

| Pre-alignment: optical / mechanical |

| ID-reader: barcode, alpha-numeric, data matrix |

| System control |

|---|

| Operations system: Windows |

| File sharing & back-up solution / unlimited no. recipes & parameters / offline recipe editor |

| Flexible process flow definition / easy drag and drop recipe programming |

| Parallel processing of multiple jobs / real-time remote access, diagnostics & troubleshooting |

| Multi-language user GUI & support: CN, DE, FR, IT, JP, KR |

Talk to our EVG product experts!

Questions?

Related technologies

Questions about our products and technologies?

Contact the EVG experts