Resist Processing Systems

The EVG100 series resist processing systems establish new standards in quality and flexibility for photoresist coating and developing. Designed to provide the widest range of process variations, the EVG100 series’ modularity offers spin and spray coating, developing, bake and chill modules to suit individual production requirements. These systems accommodate the processing of an extensive range of materials such as positive and negative resists, polyimides, double-sided coating of thin resist layers, high viscosity resists, and edge protection coatings. These systems can handle more than one substrate size, from 2" to 300 mm diameter, rectangle, square or even irregular shaped substrates, with no or very short tooling time. This allows the development of new devices or processes on an industrial level, which not only requires high flexibility but also controlled and repeatable processing. EVG has built up many years of spin and spray coating experience for demanding applications and incorporates this knowledge into the EVG100 series, where our process know-how can be leveraged to support our customers.

Choose your Resist Processing System

EVG®101

Advanced Resist Processing System

Single-wafer resist processing in R&D and small-scale production

EVG®105

Bake Module

The stand-alone EVG105 bake module is designed for soft- or post-exposure bake processes

EVG®120

Automated Resist Processing System

The EVG120 is a compact, cost-effective system for starting up production when cleanroom space is limited

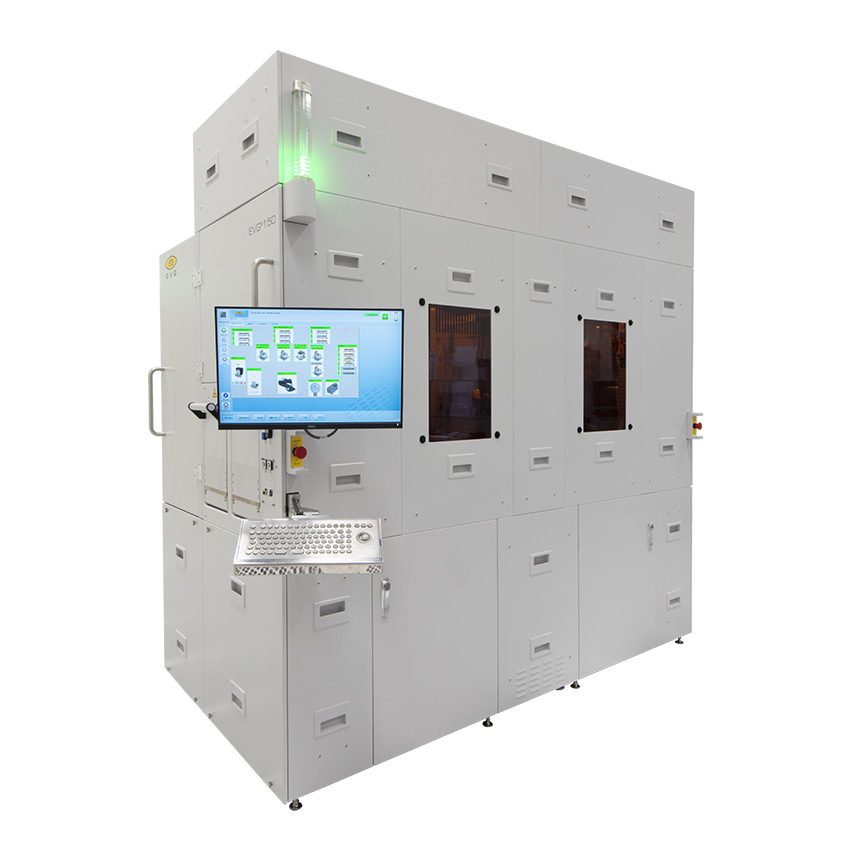

EVG®150

Automated Resist Processing System

The EVG150 is a fully automated resist processing system maintaining coat/develop process and high-throughput performance supporting wafers up to 300 mm in diameter

Talk to our EVG product experts!

Questions?

Questions about our products and technologies?

Contact the EVG experts