瞬态液相(TLP)键合

Low-temperature metal wafer bonding by Transient Liquid Phase (TLP)

Introduction

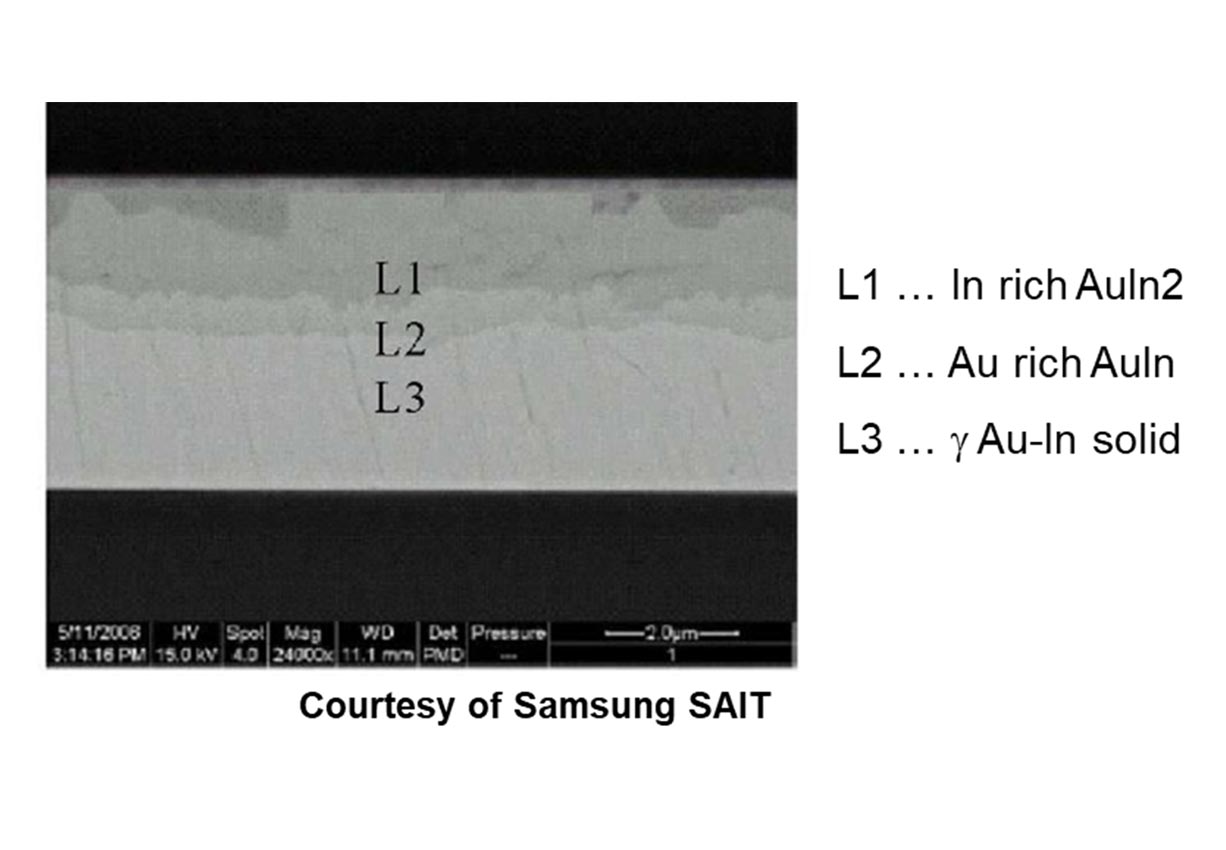

Transient Liquid Phase (TLP) bonding is often used when high-reliability bond lines or electric connections are needed. In this process, the interlayer melts, and the interlayer element diffuses into the substrate materials, thereby causing isothermal solidification. This results in a bond that has a higher melting point than the bonding temperature.

The unique characteristic feature of Transient liquid phase (TLP) bonding is that the liquid bond interface solidifies by diffusion but not by cooling below a melting point compared to eutectic bonding. This enables low process temperatures while providing much higher remelt temperature after joining the wafers. In particular, the interlayer is a low melting point material that moves into the lattice and grain boundaries of the high melting point parent materials, thereby forming an inter-metallic layer. In TLP, it is important to select a suitable interlayer based on the flow characteristics, stability and wettability in order to form a composition that provides faster diffusion characteristics and high reliability. Compared to other bonding technologies, TLP is an advanced type of solder bonding method that can form hermetic sealing at lower temperatures. It is ideal for MEMS vacuum packaging, as the process can be performed at low temperatures compatible with CMOS standards and the resulting bonded devices can withstand harsh environments with high temperatures.

Features

- Vacuum encapsulation

- Defined pressure encapsulation

- Conductive process

- Hermetic sealing

- Good mechanical strength

- Low temperature process

- Less applied force during bonding

- Very good post-bond alignment

- Applied in many metallic and ceramic systems

- Joints with uniform composition profile

Talk to our EVG technology experts!

Questions?

Questions about our technologies?

Contact the EVG experts