- Produkte

-

Technologien

- IR LayerRelease™ Technology

- MLE™ - Maskless Exposure Technologie

- Nanopräge-Lithographie (NIL) - SmartNIL®

- Wafer-Level Optics

- Optische Lithographie

- Fotolackverarbeitung

- Temporäres Bonden und De-Bonden

- Eutektisches Bonden

- Transient Liquid Phase (TLP) Bonden

- Anodisches Bonden

- Metall-Diffusionsbonden

- Hybrid- und Fusionsbonden

- Die-to-Wafer Fusion and Hybrid Bonding

- ComBond® Technologie

- Metrologie

- Unternehmen

- Karriere

Transient Liquid Phase (TLP) Bonding

Low-temperature metal wafer bonding by Transient Liquid Phase (TLP)

Introduction

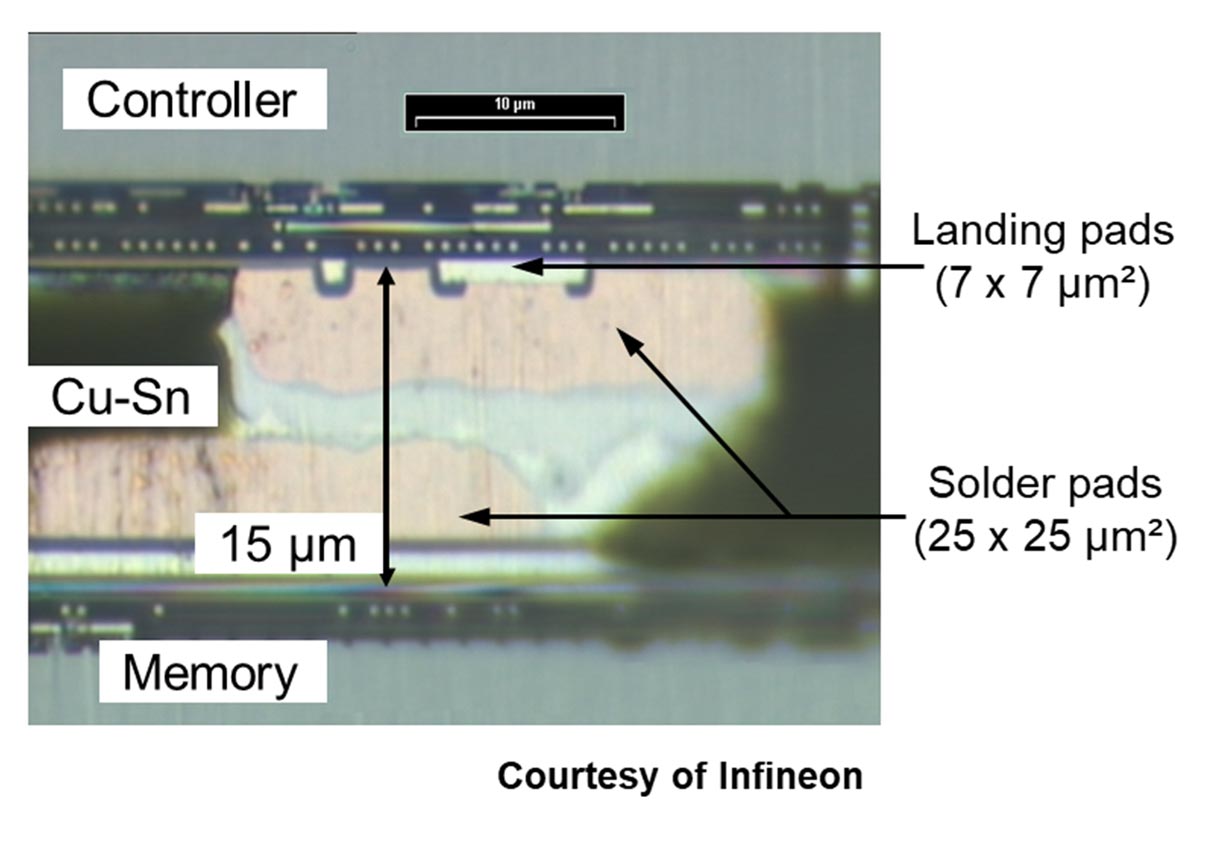

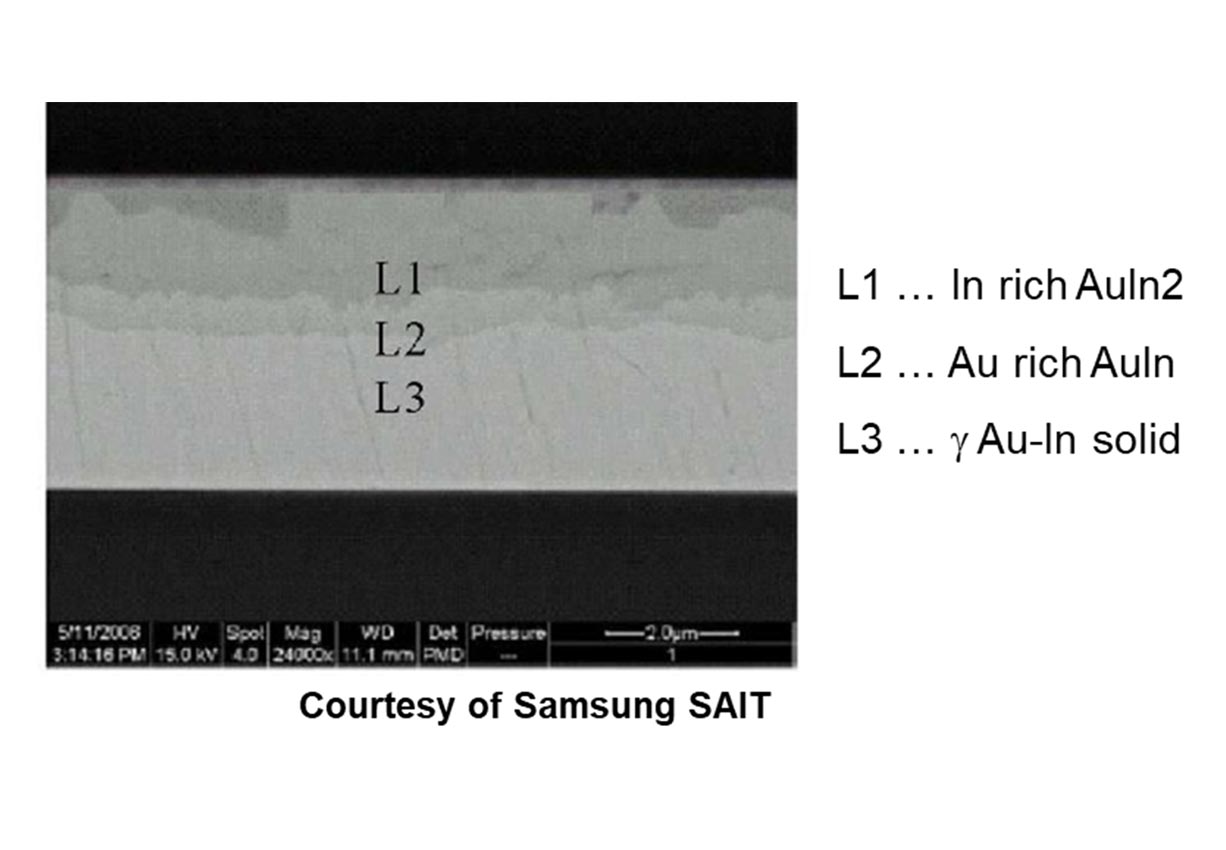

Transient Liquid Phase (TLP) bonding is often used when high-reliability bond lines or electric connections are needed. In this process, the interlayer melts, and the interlayer element diffuses into the substrate materials, thereby causing isothermal solidification. This results in a bond that has a higher melting point than the bonding temperature.

The unique characteristic feature of Transient liquid phase (TLP) bonding is that the liquid bond interface solidifies by diffusion but not by cooling below a melting point compared to eutectic bonding. This enables low process temperatures while providing much higher remelt temperature after joining the wafers. In particular, the interlayer is a low melting point material that moves into the lattice and grain boundaries of the high melting point parent materials, thereby forming an inter-metallic layer. In TLP, it is important to select a suitable interlayer based on the flow characteristics, stability and wettability in order to form a composition that provides faster diffusion characteristics and high reliability. Compared to other bonding technologies, TLP is an advanced type of solder bonding method that can form hermetic sealing at lower temperatures. It is ideal for MEMS vacuum packaging, as the process can be performed at low temperatures compatible with CMOS standards and the resulting bonded devices can withstand harsh environments with high temperatures.

Features

- Vacuum encapsulation

- Defined pressure encapsulation

- Conductive process

- Hermetic sealing

- Good mechanical strength

- Low temperature process

- Less applied force during bonding

- Very good post-bond alignment

- Applied in many metallic and ceramic systems

- Joints with uniform composition profile

Kontaktieren Sie unsere EVG-Technologieexperten!

Fragen?

Events

SEMI ISS 2026

Hören Sie sich unseren Vortrag mit dem Titel “Wafer Bonding: A Cornerstone of Future Semiconductor Architectures” präsentiert von Executive Technology Director Paul Lindner, an.

SPIE | AR | VR | MR 2026

Besuchen Sie unseren Stand #6426 und hören Sie sich unseren Vorträge an: "Advances in Dual-Side NIL: Alignment Accuracy and First-Side Protection for AR Applications" präsentiert von Business Development Manager Thomas Achleitner und in der Manufacturing Session von Dr. Thomas Glinsner.

IEEE Hybrid Bonding Symposium

Hören Sie sich unseren Vortrag “Wafer-to-wafer Bonding Overlay: Co-Optimization with Lithography and Hidden Patterns” gehalten von Business Development Manager Dr. Anton Alexeev an.

- IR LayerRelease™ Technology

- MLE™ - Maskless Exposure Technologie

- Nanopräge-Lithographie (NIL) - SmartNIL®

- Wafer-Level Optics

- Optische Lithographie

- Fotolackverarbeitung

- Temporäres Bonden und De-Bonden

- Eutektisches Bonden

- Transient Liquid Phase (TLP) Bonden

- Anodisches Bonden

- Metall-Diffusionsbonden

- Hybrid- und Fusionsbonden

- Die-to-Wafer Fusion and Hybrid Bonding

- ComBond® Technologie

- Metrologie

Fragen zu unseren Technologien?

Kontaktieren Sie die EVG-Experten