- Products

-

Technologies

- IR LayerRelease™ Technology

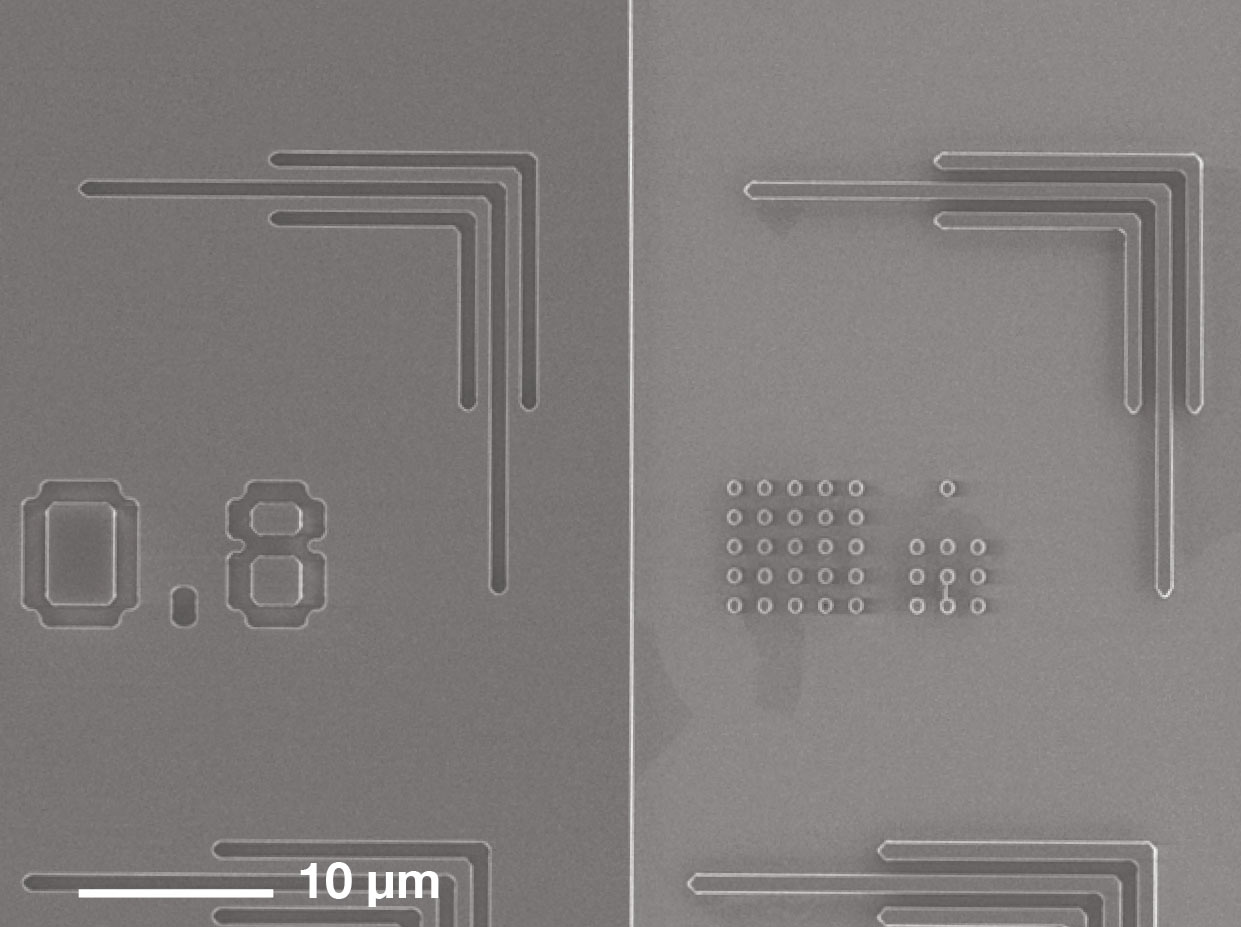

- MLE™ - Maskless Exposure Technology

- Nanoimprint Lithography (NIL) - SmartNIL®

- Wafer Level Optics

- Optical Lithography

- Resist Processing Technology

- Temporary Bonding and Debonding

- Eutectic Bonding

- Transient Liquid Phase (TLP) Bonding

- Anodic Bonding

- Metal Diffusion Bonding

- Hybrid and Fusion Bonding

- Die-to-Wafer Fusion and Hybrid Bonding

- ComBond® Technology

- Metrology

- Company

- Careers

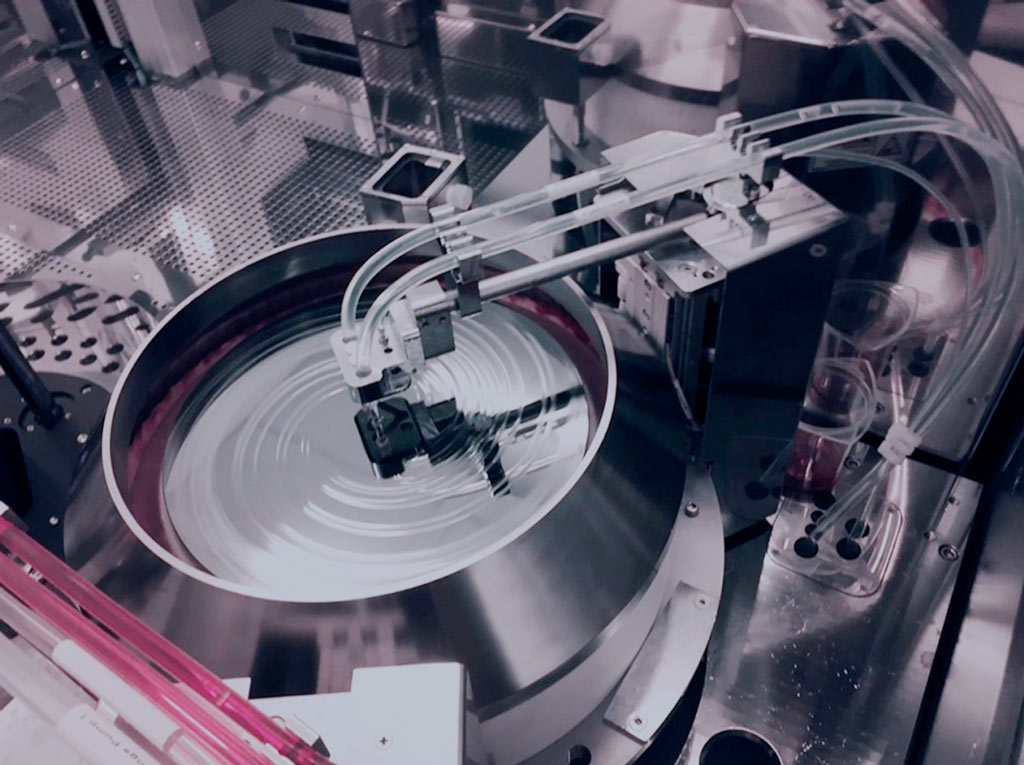

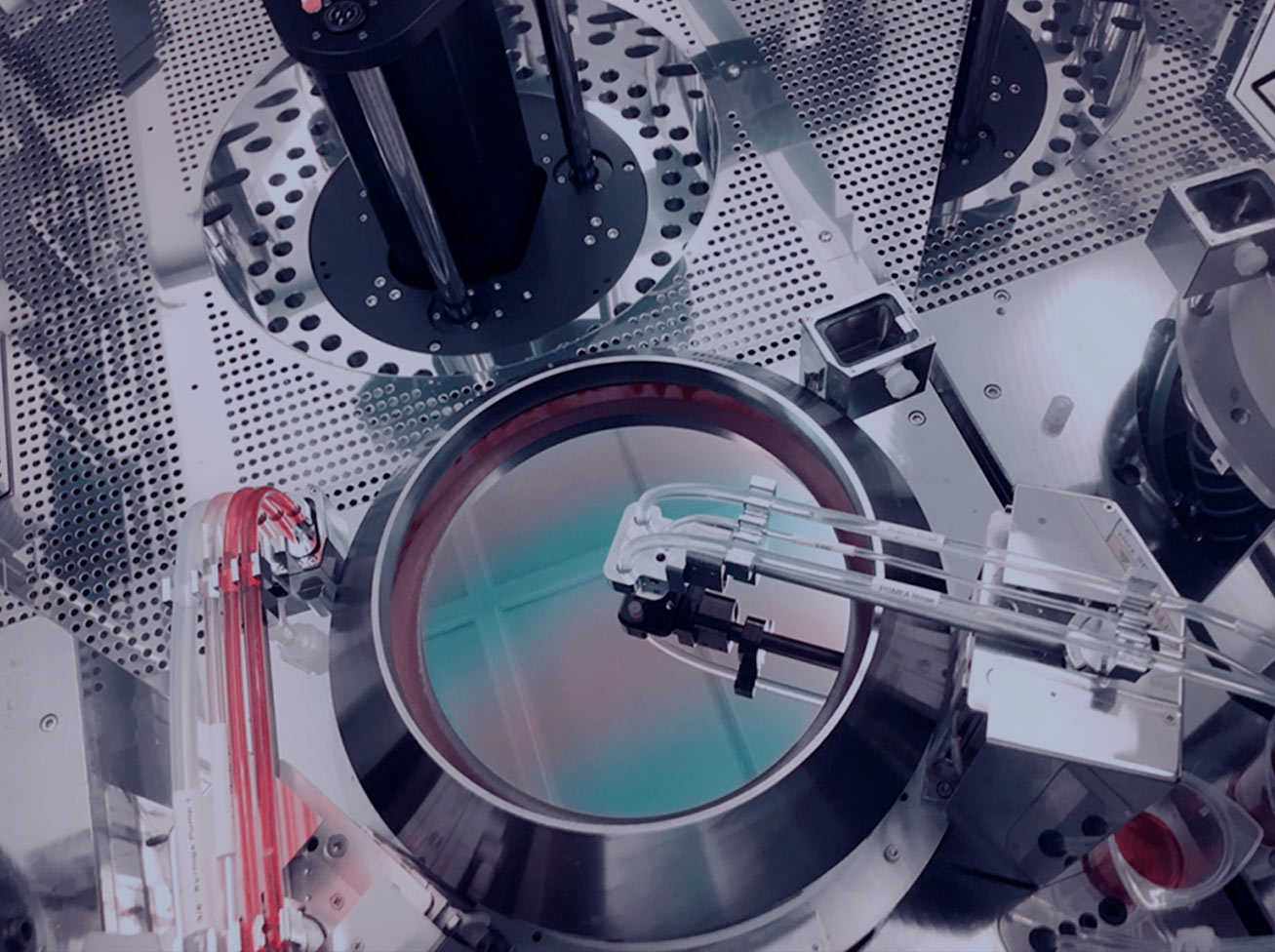

Spin Coating Technology

Spin coating still remains the preferred method of coating on planar surfaces.

Introduction

Spin coating technology is a universal and intensively used process for applying uniform thin films when no topography on the wafer is considered.

Related technologies

Dosing accuracy of dispensed material and spin speed are some of the most important factors in spin coating processes. Other critical process parameters such as acceleration, precise positioning or possibility to perform a dynamic dispense rate also play a significant role in coat properties. EVG spin coaters are designed to control all of these critical parameters to ensure precise resist dispensing process control. Up to eight dispense lines without temperature control or up to four temperature-controlled dispense lines enhance process set-up supporting three different dispense modes to guarantee optimum results for an extensive range of resists with viscosities up to 52.000 cP. Static or dynamic center dispense mode is recommended for typical thin-film applications and standard viscosity. Area dispense mode optimizes uniformity and resist consumption by enabling extremely uniform thick resist layers for the use of high-viscosity resists like BCB or SU-8. Moreover, edge dispense mode is a typical application for etch protection purposes, especially for long-term etch processes. For this purpose, EVG systems are equipped with programmable swivel arms supporting various flat/notch designs. Additional functions – such as solvent-based pre-wetting, edge-bead removal and automatically solvent refillable sealed park position – support advanced process control and production requirements. The programmable suck-back function prevents surplus resist from dropping out of the nozzle tip on the wafer surface and thus secures conformal results throughout the whole wafer. Optional CoverSpin reduces the amount of resist material per wafer and avoids edge turbulence effects independent of the substrate shape. Overall, EVG’s spin coat module with a simulation-based low-turbulence design effectively supports resist-saving processes while providing high-uniformity results on planar or low-topography surfaces.

Features

- Precise recipe-controlled resist dispensing process

- Three different dispense modes for extensive range of photoresists with viscosities up to 52000 cP

- Simulation-based low-turbulence design of coat module geometry

- Programmable swivel arm supporting various flat/notch designs

- Advanced process control with additional functions such as solvent-based pre-wetting or edge-bead removal

- Automatically solvent refillable sealed park position

- Programmable suck-back function

- CoverSpin™ technology for improved coating uniformity and eliminated edge effects independent of the substrate shape

- Smart process control and data analysis software features

- Integrated analysis features for process and machine control

- Parallel task/queueing task processing feature

- Equipment and process performance tracking feature

- Smart handling features

- Occurrences and alarms analysis

- Smart maintenance management and tracking

Talk to our EVG technology experts!

Questions?

Events

ICEP 2025

Listen to our talks "Wafer Bonding Advances & 3D Applications" held by our Representative Director Hiroshi Yamamoto on 9:30 Wednesday, April 16 / Room B and "Hybrid Bonding for Heterogenous Integration" held by our Process Technology Manager Europe Gerald Mittendorfer on 12:40 Friday, April 18 / Room A.

JFS Conference and Compoundsemiconductor Industry Expo 2025

Visit our booth #A308

MicroNanoFabrication Annual Review Meeting 2025

Visit our booth at the MicroNanoFabrication Annual Review Meeting 2025!

- IR LayerRelease™ Technology

- MLE™ - Maskless Exposure Technology

- Nanoimprint Lithography (NIL) - SmartNIL®

- Wafer Level Optics

- Optical Lithography

- Resist Processing Technology

- Temporary Bonding and Debonding

- Eutectic Bonding

- Transient Liquid Phase (TLP) Bonding

- Anodic Bonding

- Metal Diffusion Bonding

- Hybrid and Fusion Bonding

- Die-to-Wafer Fusion and Hybrid Bonding

- ComBond® Technology

- Metrology

Questions about our technologies?

Contact the EVG experts