- Products

-

Technologies

- IR LayerRelease™ Technology

- MLE™ - Maskless Exposure Technology

- Nanoimprint Lithography (NIL) - SmartNIL®

- Wafer Level Optics

- Optical Lithography

- Resist Processing Technology

- Temporary Bonding and Debonding

- Eutectic Bonding

- Transient Liquid Phase (TLP) Bonding

- Anodic Bonding

- Metal Diffusion Bonding

- Hybrid and Fusion Bonding

- Die-to-Wafer Fusion and Hybrid Bonding

- ComBond® Technology

- Metrology

- Company

- Careers

Temporary Bonding and Debonding

Temporary bonding and debonding enabling backside processing for 3D integration

Introduction

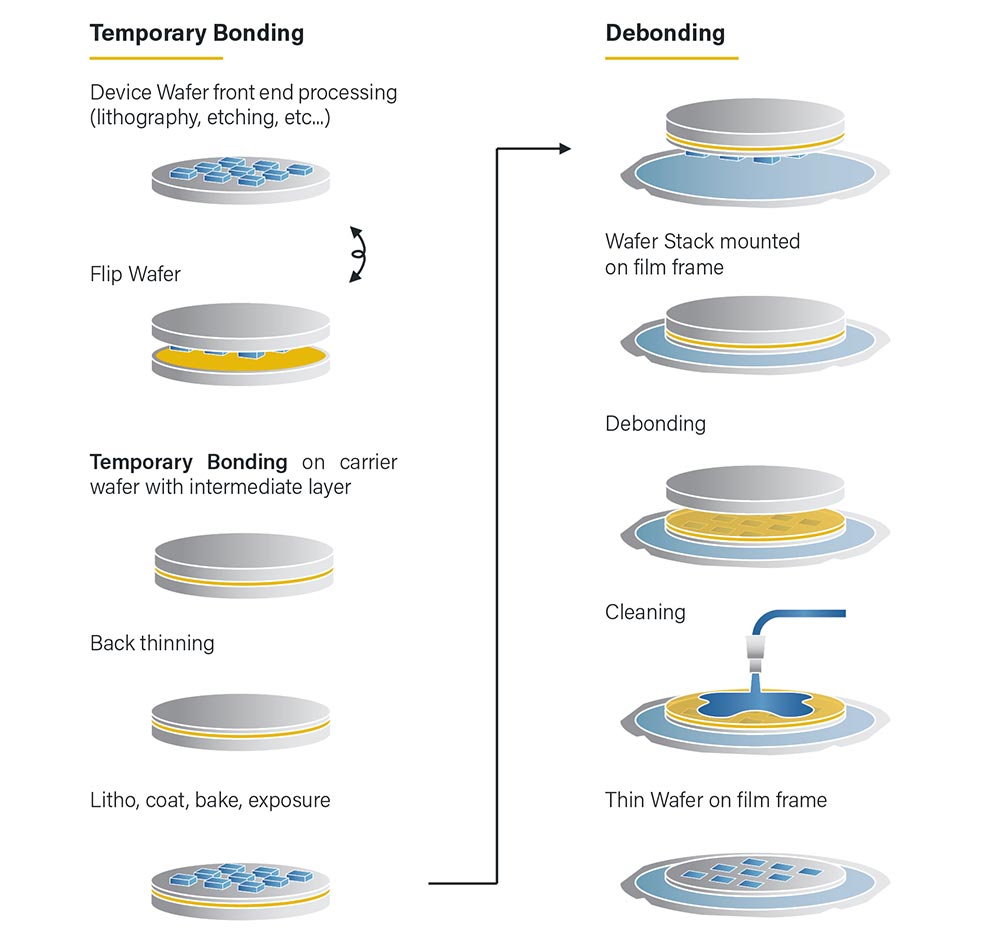

Temporary bonding is an essential process for enabling wafer thinning and for supporting thin-wafer transfer. This is key for advanced packaging, including 2.5D, 3D IC and Fan-out Wafer-level Packaging (FoWLP) wafers, for power devices, as well as for handling fragile substrates like compound semiconductors and MEMS wafers. EVG’s outstanding wafer bonding know-how includes temporary bonding and debonding equipment, which EVG has been providing to leading fabs, foundries and packaging companies since 2001.

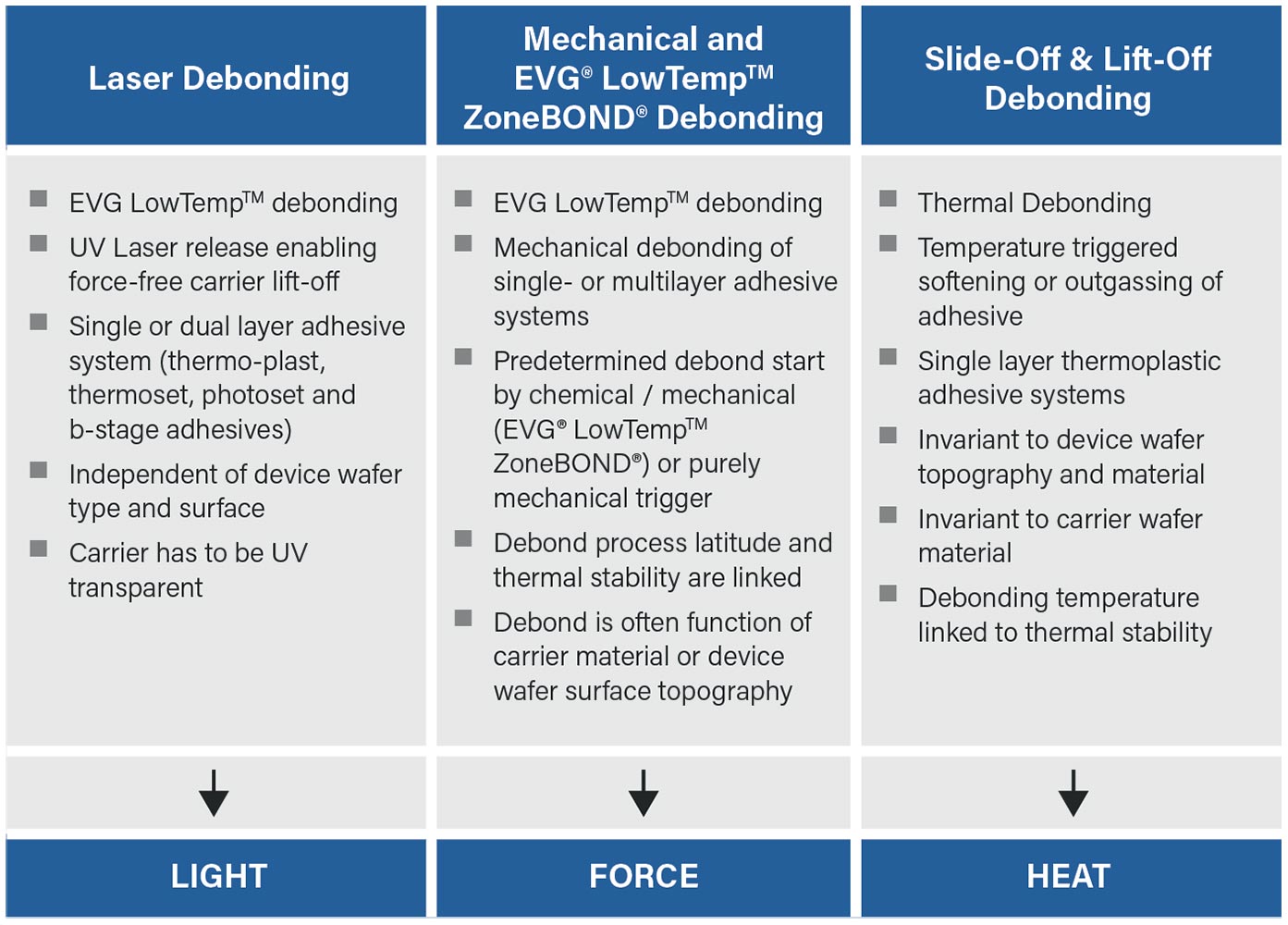

EVG’s most recent innovations in debonding technologies are UV and IR laser debonding, with a wide process window and LowTemp debonding for smooth process integration, enabling the production of ultra-thin chips and packages for next-generation devices. These debonding technologies complement EVG’s thermal slide-off debonding, which was the first debonding technology implemented in HVM production for advanced packaging.

EVG’s open adhesive platform, that supports all commercially available adhesive materials in combination with the different debonding technologies, enables tailored solutions for a wide range of applications with special requirements.

- Thermal slide-off debonding utilizes the softening of thermoplastic adhesives at elevated temperatures to separate the device wafer from the carrier.

- UV laser debonding separates the device wafer and the UV transparent carrier wafer by decomposing the UV laser release layer without risking the device wafers’ integrity.

- IR laser debonding (LayerRelease) is compatible with silicon carrier wafers with an inorganic IR laser release layer, which is cleanable with inorganic solvents.

Features

- Open adhesive platform

- Thermal Slide-Off, UV Laser or IR Layer Release Debonding

- Modular tool layout for throughput optimization

- Bridge capability for different substrate sizes

- Available with multiple load port options and combinations

- Film Frame, stand-alone wafer, or thin-wafer carrier as output options

- Integrated metrology enables feedback loop for high-yield processes in automated tools

- Software monitoring of the whole process for equipment performance tracking

- Fully integrated SECS/GEM interface in automated tool

Related products

Talk to our EVG technology experts!

Questions?

- IR LayerRelease™ Technology

- MLE™ - Maskless Exposure Technology

- Nanoimprint Lithography (NIL) - SmartNIL®

- Wafer Level Optics

- Optical Lithography

- Resist Processing Technology

- Temporary Bonding and Debonding

- Eutectic Bonding

- Transient Liquid Phase (TLP) Bonding

- Anodic Bonding

- Metal Diffusion Bonding

- Hybrid and Fusion Bonding

- Die-to-Wafer Fusion and Hybrid Bonding

- ComBond® Technology

- Metrology

Questions about our technologies?

Contact the EVG experts