- Products

-

Technologies

- IR LayerRelease™ Technology

- MLE™ - Maskless Exposure Technology

- Nanoimprint Lithography (NIL) - SmartNIL®

- Wafer Level Optics

- Optical Lithography

- Resist Processing Technology

- Temporary Bonding and Debonding

- Eutectic Bonding

- Transient Liquid Phase (TLP) Bonding

- Anodic Bonding

- Metal Diffusion Bonding

- Hybrid and Fusion Bonding

- Die-to-Wafer Fusion and Hybrid Bonding

- ComBond® Technology

- Metrology

- Company

- Careers

Die-to-Wafer Bonding Systems

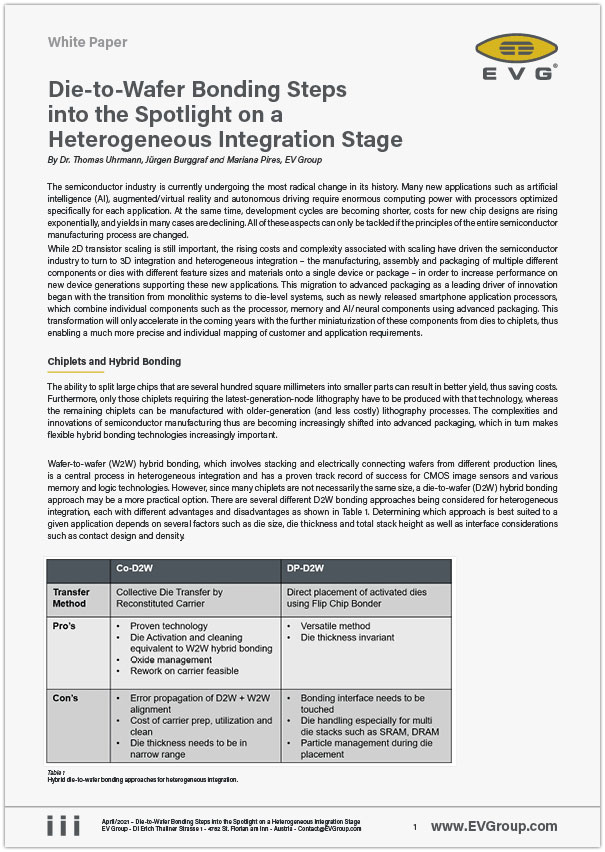

Several different D2W bonding methods are available and selected depending upon the application and customer requirements. In direct placement D2W (DP-D2W) bonding, the singulated dies are bonded to the target wafer one by one using a pick-and-place flip-chip bonder. Plasma activation and cleaning of the surfaces of the dies on the handler wafer are essential steps for establishing a high-yielding bond and electrical interface between the dies and target wafer. This is where the EVG320 D2W activation system comes in.

Choose your Die-to-Wafer Bonding System

EVG®320 D2W

Automated Die Preparation and Activation System

Industry’s first commercially available hybrid bond activation and cleaning system for direct placement (DP) die-to-wafer (D2W) bonding

GEMINI® FB Automated Fusion Wafer Bonding System Configured for Die-to-Wafer Bonding

Automated Collective Die-to-Wafer Bonding System

High volume manufacturing system for collective die-to-wafer (Co-D2W) bonding

Talk to our EVG product experts!

Questions?

Questions about our products and technologies?

Contact the EVG experts