- Produkte

-

Technologien

- IR LayerRelease™ Technology

- MLE™ - Maskless Exposure Technologie

- Nanopräge-Lithographie (NIL) - SmartNIL®

- Wafer-Level Optics

- Optische Lithographie

- Fotolackverarbeitung

- Temporäres Bonden und De-Bonden

- Eutektisches Bonden

- Transient Liquid Phase (TLP) Bonden

- Anodisches Bonden

- Metall-Diffusionsbonden

- Hybrid- und Fusionsbonden

- Die-to-Wafer Fusion and Hybrid Bonding

- ComBond® Technologie

- Metrologie

- Unternehmen

- Karriere

Permanent Bonding Systems

The introduction of EVG's wafer-bonding approach, which separates the bond alignment from the bonding step, immediately revolutionized the market. Utilizing high-contact forces under elevated temperatures and a controlled atmosphere, this novel approach is today's process standard, with EVG holding the dominant market share for both semi- and fully automated wafer bonders and a growing installed base of more than 1500 chambers. EVG's wafer bonders offer optimal total cost of ownership (TCO), as well as multiple design features to optimize bonding yield. Multiple modules for bond alignment are optimized for different market requirements in MEMS, 3D integration or advanced packaging. Industry-leading alignment accuracies of less than 100 nm and a high-volume-proven modular platform enables the combination of EVG’s wafer bonding technologies in various applications.

Choose your Permanent Bonding System

EVG®501

Wafer Bonding System

Versatile manual wafer bonding system for academia and industrial research

EVG®510

Wafer Bonding System

Wafer bonding system for R&D or low-volume production - fully compatible with high-volume-manufacturing equipment.

EVG®520 IS

Wafer Bonding System

Single or dual chamber wafer bonding system for low volume production.

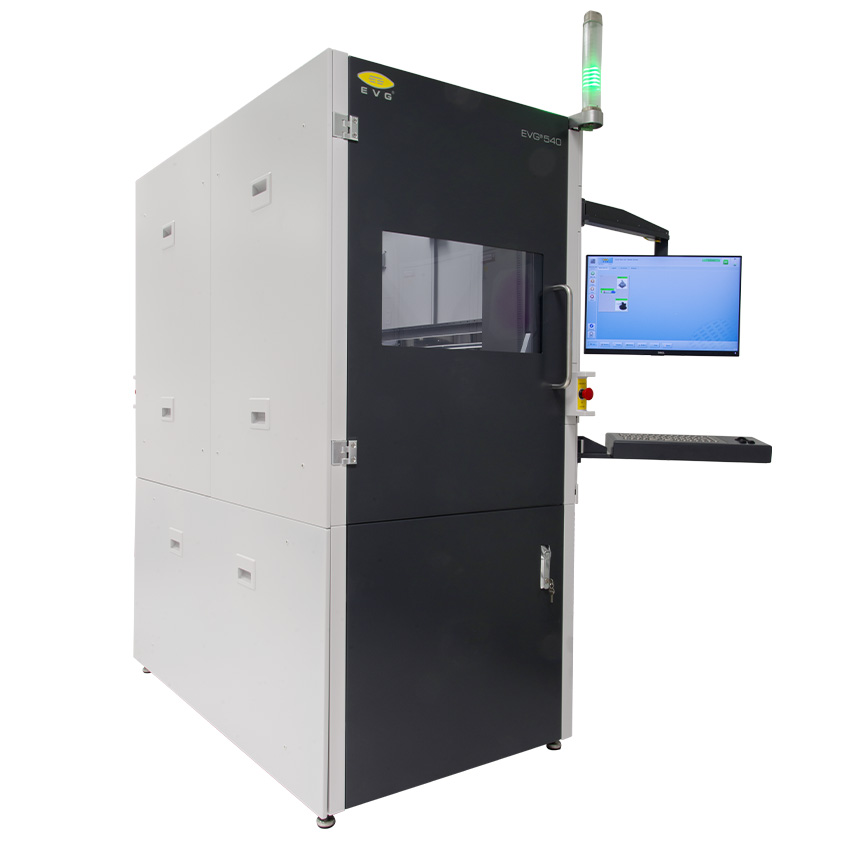

EVG®540

Automated Wafer Bonding System

Fully automated wafer bonding system for substrates up to 300 mm.

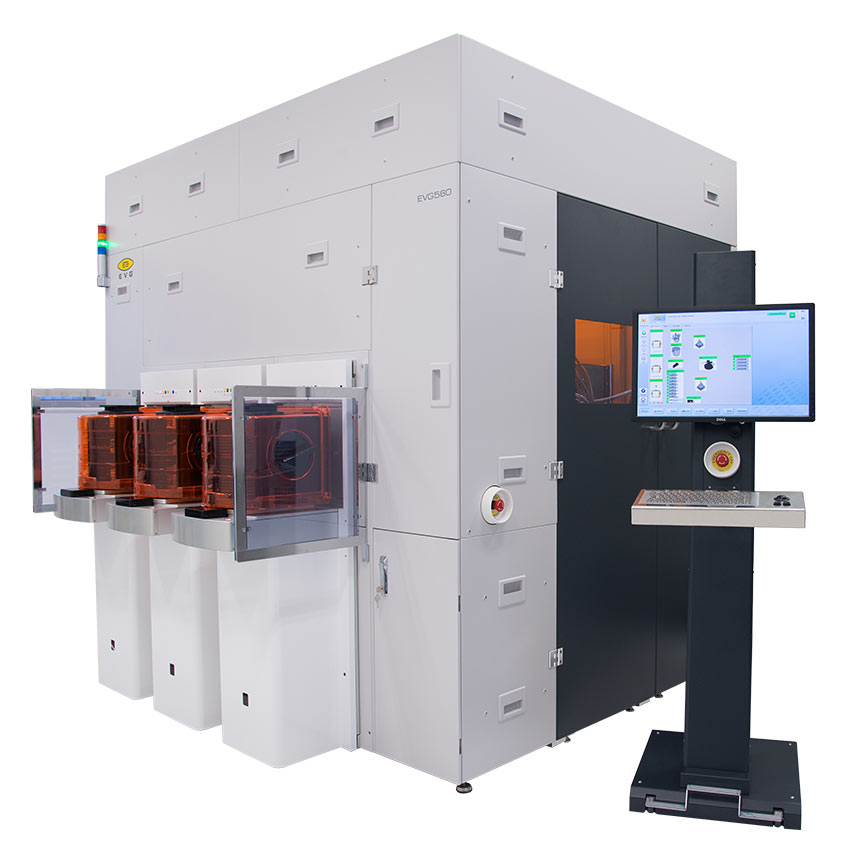

EVG®560

Automated Wafer Bonding System

Fully automated wafer bonding system for high-volume manufacturing.

ComBond®

Automated High-Vacuum Wafer Bonding System

High-vacuum wafer bonding platform facilitating covalent bonds of “anything on anything”.

GEMINI®

Automated Production Wafer Bonding System

Integrated modular high-volume manufacturing system for aligned wafer bonding.

Talk to our EVG product experts!

Questions?

Questions about our products and technologies?

Contact the EVG experts